What are the most critical quality checks for Interactive Panels?

What are the most critical quality checks for Interactive Panels?

Quality tests that are conducted by the manufacturer is mission critical to the longevity of the product.

And, unless the manufacturer owns the manufacturing process, we wouldn’t be sure, how much control the manufacturer would have in the overall Quality control of the products.

There are multiple critical quality tests that are required to ship out an interactive panel to a classroom. If any of these tests are not done, or the manufacturer does not report results of such tests, you would be in dark and would only be making a purchase trusting their marketing gimmick, literature, on your face discounts and sweet talks. We would not recommend investing on such a product and company that does not have full autonomous control on quality and does not have specific reports on Quality tests that are conducted.

Here are some of the critical quality tests that must be conducted on an interactive panel and your manufacturer should be forth coming in sharing the details of the same with you:

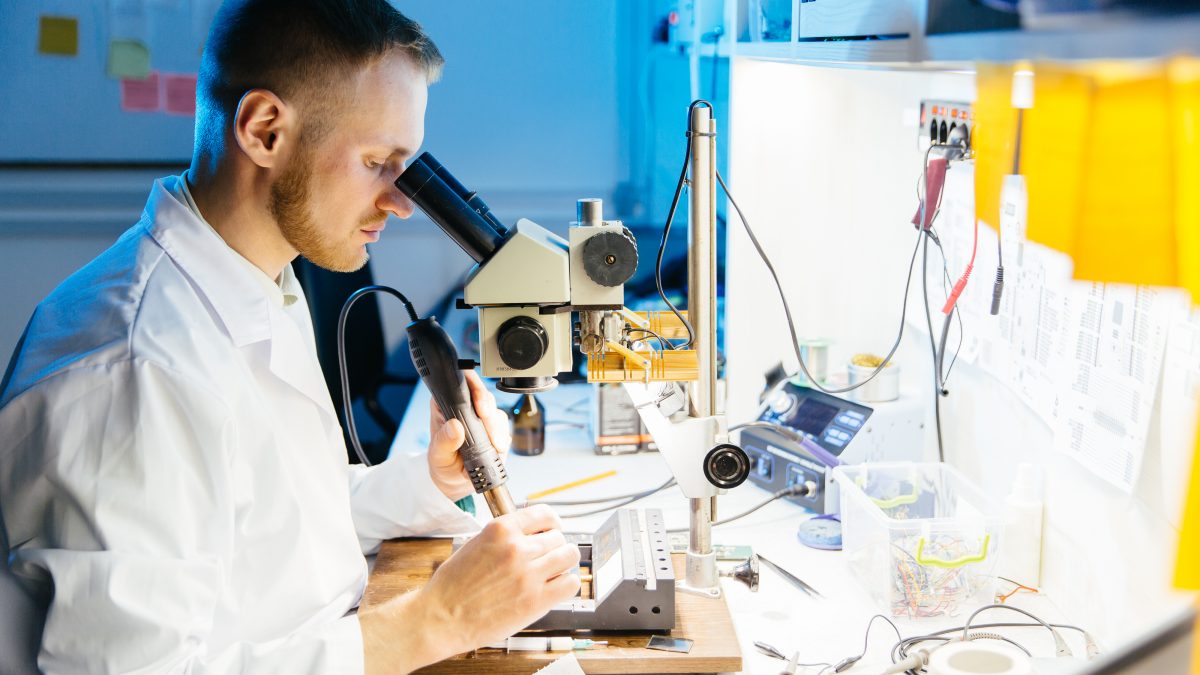

1. Automated PCB functionality test

PCB (Printed circuit board) functional testing is the most important test in the electronics manufacturing process, which when done correctly prevents larger damage control when the product is in the market and is being used, and ensures the product will not fail or have a shortened service line.

Senses Electronics does conduct and share details of the automated PCB functionality testing that is done for each of its products that comes out of its assembly line. While other manufactures, mostly rely on their partners in China to validate the testing and quality control processes.

2. Panel Colour Test

This is important considering that you will typically mount your interactive panels in your classrooms to be viewable by a large set of students, with varying viewing angles and distances. You will want your teachers to be able to use interactive and high resolution content to provide the experience to students in the classrooms that you are investing for. Panel colour test includes the following checks, test pattern, defective pixels, uniformity, colour distances, gradients, sharpness, viewing angles, Gamma, response time, and Panel white dot test.

3. CPU Burn-in test

During a CPU burn-in test or stress test, the system is run with a very heavy load at maximum processing capability for an extended period of time to check if anything fails. This essentially puts a 100% load on the CPU of the interactive panel for an extended period of time and is useful for testing system stability, cooling solutions, thermal throttling, etc.

Senses Electronics does a CPU burn-in test of two hours.

4. System life test

System life test or full system life testing conducted my manufacturers helps uncover design defects or weaknesses that may not have been realized during product design, manufacturing, or assembly. This is done through simulation of “real-life” conditions and provides data necessary to evaluate performance, and reliability of the products.

Senses Electronics conducts system life test at excruciating levels of 70-degree temperature and at 85% humidity levels for 24 hours.

Along with other standard quality control processes, the one listed above are necessary evils that you must check for and get detailed information from your manufacturer before purchasing interactive panels for your classrooms.

If your manufacturer is offering you an attractive pricing, try and figure what compromises are you signing up for that will hurt you and your investment in the future. Go visit their factories once if you have to, but make sure you are checking these aspects.

For more information about Senses Interactive panels write tosales@senseselec.com of call +91 70668 40505

CLICK HERE TO WATCH A FREE DEMO

Online class